Project:

Volcano Bay – Universal Orlando

YEAR:

2018

LOCATION:

Orlando, Florida

PROJECT SUMMARY:

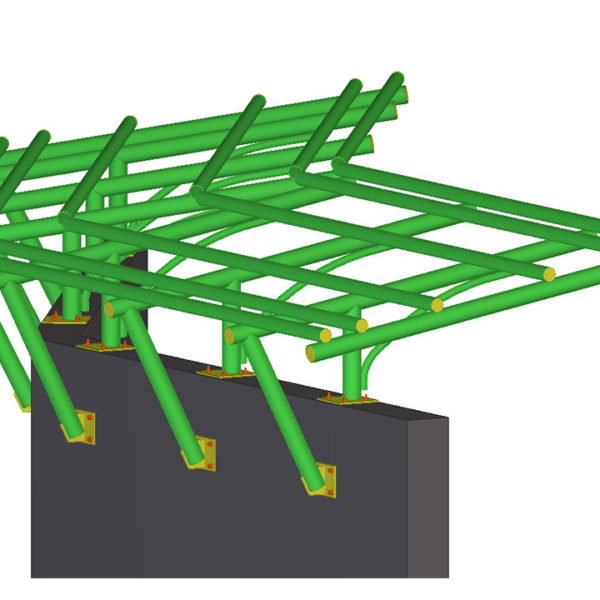

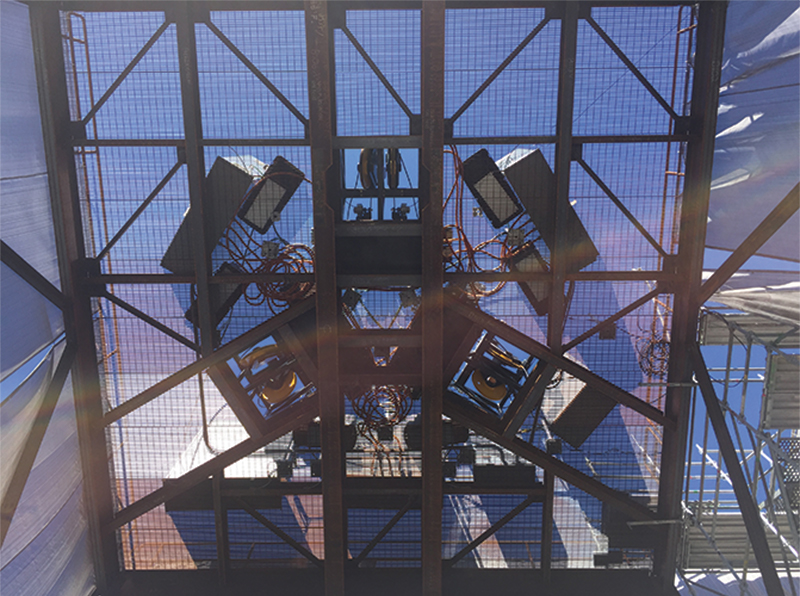

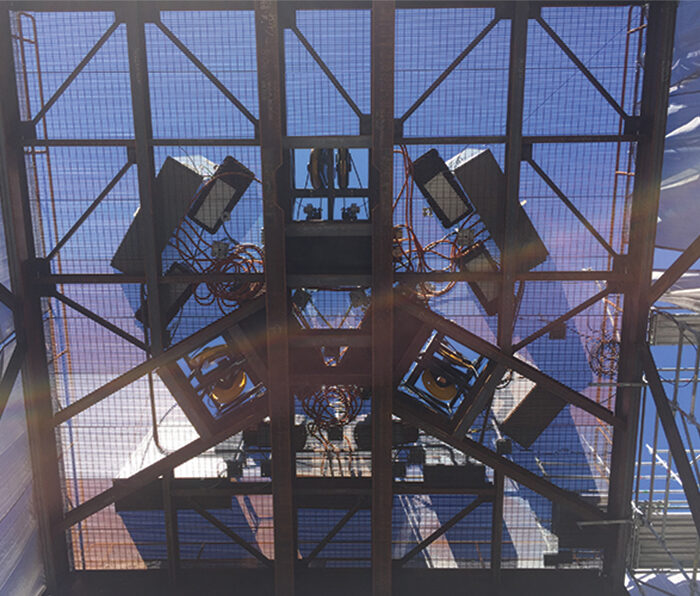

After operating the brand new Volcano Bay water park for a summer season, Universal Creative decided to provide more weather protection for the guests. Eight shade structures, which we built, provide protection from the intense sun and shelter during thunderstorms. These structures are located throughout the park on beach sand and, as always, we had to erect them in the middle of the night so that the guests were absolutely not disturbed. These hip structures are fully bolted and even the roof deck was cut to the exact size and shape in our shop. We decided to weld the deck instead of using powder-actuated pins, thereby reducing construction noise for the Cabana hotel guests nearby. A large telescoping forklift with a boom extension was used to reach all the locations. We stayed mostly off the sand as we feared it could easily get stuck. The consequences would have been catastrophic if that happened. It’s very important for these parks for contractors to come out, do their work and pull out on time, without leaving a trace. Once we finished our contract, another crew came in, cladding the structure in wood, attached the thatching and installed the lights.

Recent Comments